Full control. Maximum efficiency. Design without compromise. MoldControl / servomold

MoldControl from servomold is a new generation of servo-electric automation solutions for injection molding processes. The new user interface designed by HMI Project forms a functional and creative unit with the closely coordinated industrial design of the control panel and focuses on a high level of user-friendliness. Clear process visualizations, the simplification of the most complex interrelationships and the clear display of all important parameters and functions give the user 100% control over the running process. The new and innovative operating concept offers full flexibility for efficient and optimized production.

Challenges and Applications

Servomold offers customized servo system solutions of all kinds, which are used, for example, in the medical technology and pharmaceutical sectors. Across all industries, the focus is always on precise, clean and efficient production with high process reliability and availability. The task was therefore to develop an HMI system that could be flexibly adapted to a wide variety of production environments and individual requirements. At the same time, complex interrelationships were to be rethought and made accessible in the simplest and most comprehensible visualizations possible.

Real-time efficiency

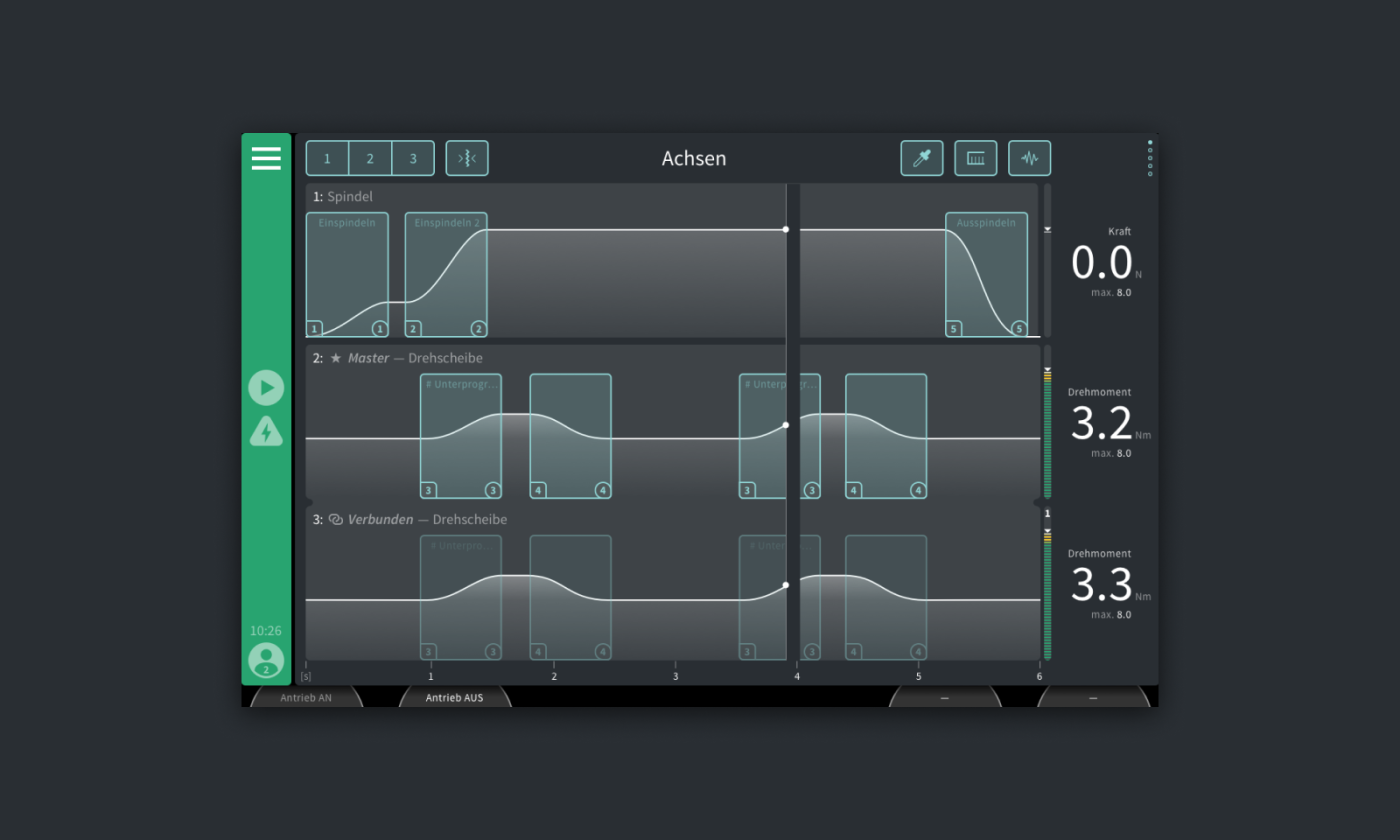

With the new editing function in MoldControl, it is possible to intervene in the production process at any time - even during an ongoing injection molding process. Irregularities can thus be rectified more quickly and downtimes reduced many times over. In addition, intuitively operable movement segments, clear monitoring views and various intelligent auto-tuning functions and plausibility checks give users full control over the complex production process at all times.

Focus on individuality

The new user interface is also characterized by a high degree of flexibility. The displayed content is highly customizable, so that the right focus can be set depending on the user level or current task.

The extensive program and variable editor integrated directly into the HMI also offers the option of configuring tailor-made sequence programs in no time at all. Even the most complex process sequences can be easily implemented without any programming effort.

Maximum process control

Die mit MoldControl durchgeführten Prozesse sind vor allem eines: hochkomplex. Wir haben es uns zur Aufgabe gemacht, dieser Komplexität mit übersichtlich aufbereiteten und leicht lesbaren Informationen in Form von Informationsgrafiken, Parameterdarstellungen, Prozess- und Statusvisualisierungen entgegenzuwirken. Dadurch ist es den User:innen möglich, alle wichtigen Informationen schnell zu erfassen und das Einrichten und Bedienen der Maschine in kürzester Zeit zu erlernen.

Consistent design

When designing the new HMI, particular attention was paid to ensuring that the servomold brand was highly recognizable. Accordingly, colors and fonts were derived from the company's CI. In addition, the interface and the industrial design of the machine, developed by Kay Saamer, were precisely coordinated so that users are presented with a uniform and coherent overall picture.

Vimeo

External Video

We host our videos on Vimeo. When the videos load, a connection to Vimeo servers is established and cookies are set (possibly also from Vimeo).

Privacy