The Innovative Solution for Packaging Machines New Rovema HMI / Rovema

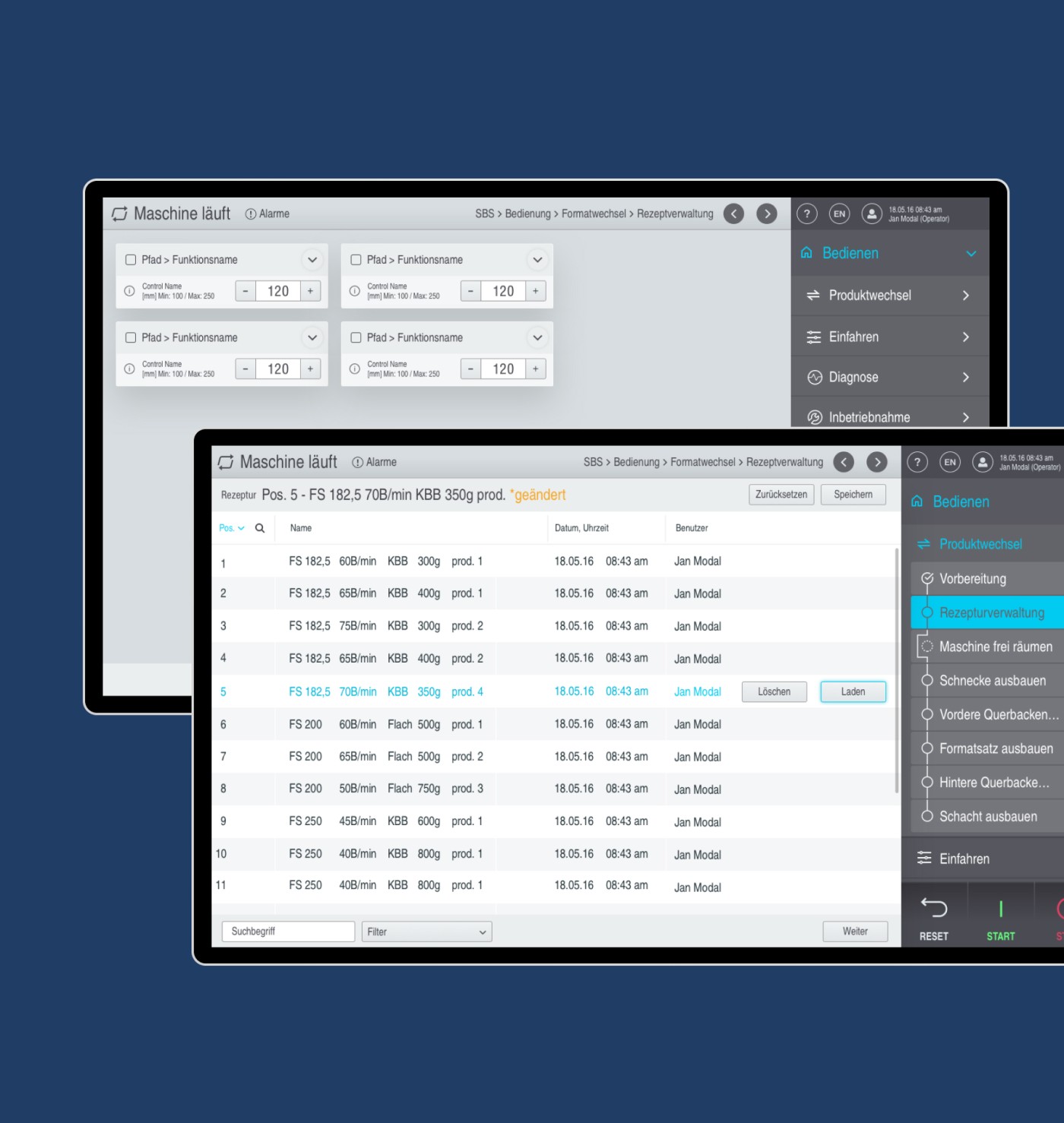

Rovema's new HMI is a touch-optimized user interface for packaging machines and lines that covers the entire packaging process: from dosing to form, fill, and seal machines, to complete packaging systems, including end-of-line packaging, for a variety of different products and applications in the food and non-food sectors. The user interface features a fully customizable HMI that adapts to various screen sizes and input methods.

Challenge and Usage

Rovema offers a diverse range of machine types, from individual units to fully integrated packaging lines, all tailored to the specific requirements and products of individual customers. With a focus on adaptability and scalability, these machines are carefully designed and configured directly on the Human-Machine Interface (HMI) to ensure seamless integration into the heterogeneous operational contexts of various industries. Rovema's high level of automation simplifies complex on-site commissioning processes and guarantees optimal performance and adaptability to evolving customer needs.

Touch-optimized Operation

The modular structure and consistent appearance work for all machine types. Multi-touch capability is also included, making it suitable for monitoring individual machines as well as complex lines. For even smoother operation, day-to-day tasks are separated from the setup function. Intuitive operation through active user guidance and supported operation via workflows and step-by-step instructions assist the user in abstract navigation.

Vimeo

External Video

We host our videos on Vimeo. When the videos load, a connection to Vimeo servers is established and cookies are set (possibly also from Vimeo).

PrivacyResponsive and Flexible

The user interface prioritizes scalability, responsiveness, and consistency across all devices. It ensures a seamless experience with predefined design rules and touch-optimized ergonomics. The modular architecture enables cost-effective management and updates. Key functionalities are easily accessible thanks to intuitive navigation and active support. Adaptability to different users and contexts is supported by clear status indicators and a graphical user interface for tasks such as diagnostics and notifications.

To the Future with Helio

We implemented the frontend using web technology. This led to the first need for a web-based Content Management System. This CMS can be individually edited. It features a custom library of high-quality core components, as well as automatic versioning and recovery functionality. The system supports internationalization and localization. It also has a fully functional live preview with real backend data and unlimited content scalability.

The system was developed by us according to very specific requirements for Rovema. This gave rise to the idea for HELIO, an HMI editor that allows user-centered HMIs to be created without programming effort. This concept was subsequently transformed by us into a product development.

The result is not only easy to use - HELIO is also quick and easy to learn, which helps to significantly reduce development costs for other machine and plant manufacturers.

For more information, visit helio-hmi.com